The theoretical concept was to develop performance brake pads that comply to a wide array of driving situations and enthusiast needs for European automobiles. Satisfying the customer’s vision of their ideal braking system is not possible without understanding the use and purpose of the vehicle. In this world, a perfect brake pad that produces no dust and no noise that complies to racing / sport driving simply does not exist. We have discovered that developing pads that are decently balanced in their properties suits the user’s highest demands the best. For the most ideal brake pads, iSWEEP is the answer.

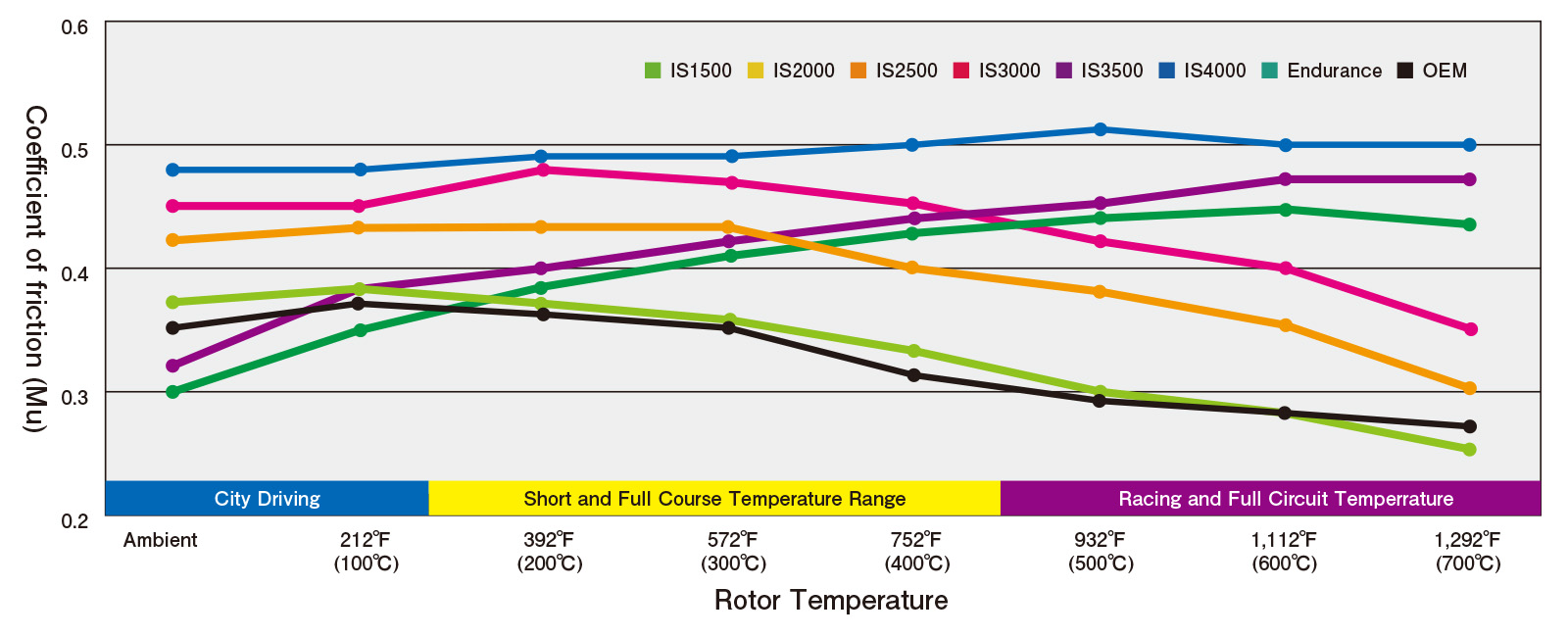

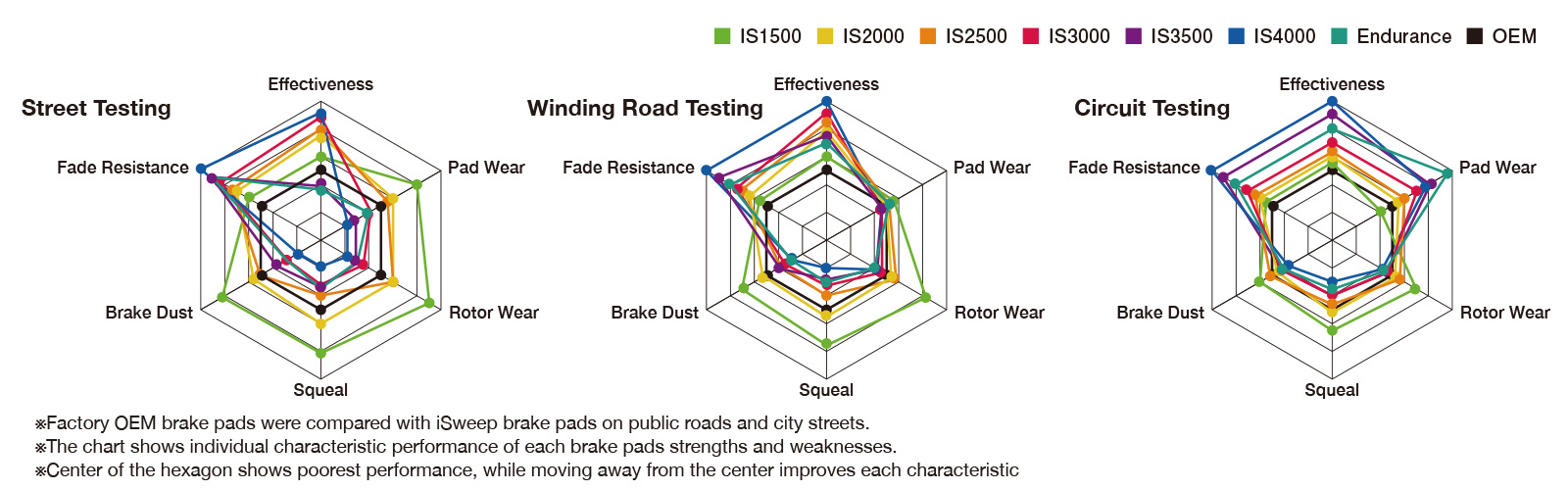

The essential part of brake pad development is choosing the right frictional material in order to exhibit the ideal brake characteristics to suit its targeted usage. Usually the formula requires a compromise; for example, a quiet and noise-free pad cannot be guaranteed against brake fade characteristics, at times increasingly more worse than factory brake pads. A balance of braking properties are very important as well, such as if the effectiveness of the pad compound is increased, so must the initial braking characteristic for which both are correlated with the pedal control factor. Typically, the more experienced the driver, the more they will request for a pad with increased linear braking characteristic with high fade resistance. Seven varying frictional levels and characteristics have been developed to suit a wide array of user needs. These brake pads have undergone rigorous testing such as long-term street testing and countless data logging from circuit use to bring to you the most ideal iSWEEP brake pad.

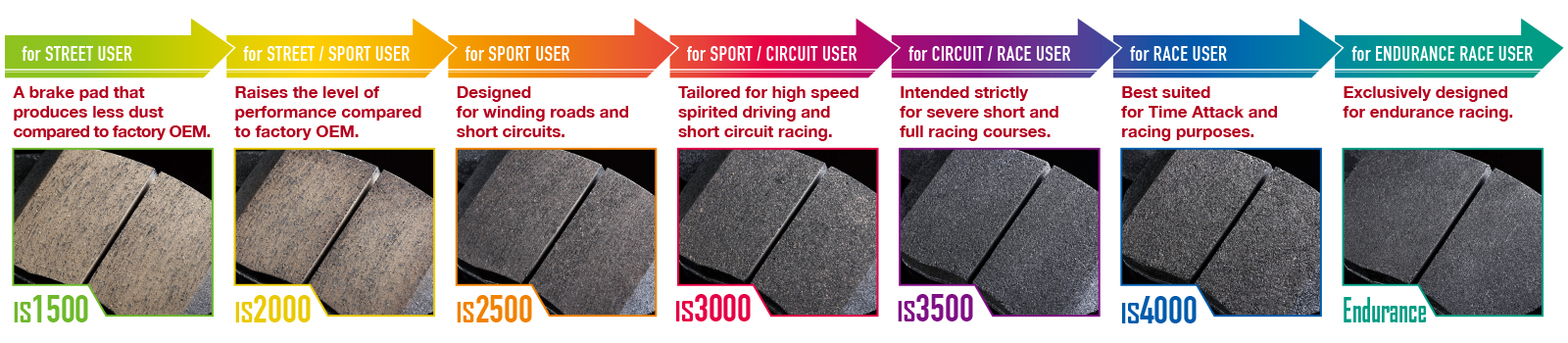

A brake pad that produces less dust compared to factory OEM.

| USE | High Performance Street |

|---|---|

| Material | Non-Steel |

| Temperature Range | Ambient~842℉(450℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.35~0.38 |

| Coefficient 752~1,292℉(400~700℃) |

0.28~0.30 |

Raises the level of performance compared to factory OEM.

| USE | High Performance Street Winding Roads |

|---|---|

| Material | Non-Steel |

| Temperature Range | Ambient~1,022℉(550℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.40~0.42 |

| Coefficient 752~1,292℉(400~700℃) |

0.35~0.38 |

Designed for winding roads and short circuits.

| USE | Winding Roads Mini-Circuit |

|---|---|

| Material | Low-Steel |

| Temperature Range | Ambient~1,112℉(600℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.42~0.45 |

| Coefficient 752~1,292℉(400~700℃) |

0.37~0.40 |

Tailored for high speed spirited driving and short circuit racing.

| USE | Winding Roads Mini-Circuit |

|---|---|

| Material | Low-Steel |

| Temperature Range | Ambient~1,202℉(650℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.45~0.48 |

| Coefficient 752~1,292℉(400~700℃) |

0.40~0.42 |

Intended strictly for severe short and full racing courses.

| USE | Mini-Circuit Full-Cicuit |

|---|---|

| Material | High-Steel |

| Temperature Range | 392~1,382℉(200~750℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.33~0.35 |

| Coefficient 752~1,292℉(400~700℃) |

0.45~0.47 |

Best suited for Time Attack and racing purposes.

| USE | Time Attack Full Race |

|---|---|

| Material | High-Steel |

| Temperature Range | 212~1,562℉(100~850℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.47~0.49 |

| Coefficient 752~1,292℉(400~700℃) |

0.49~0.51 |

Exclusively designed for endurance racing.

| USE | Endurance Racing |

|---|---|

| Material | High-Steel |

| Temperature Range | 572~1,382℉(300~750℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.35~0.38 |

| Coefficient 752~1,292℉(400~700℃) |

0.43~0.45 |