PRODUCTS

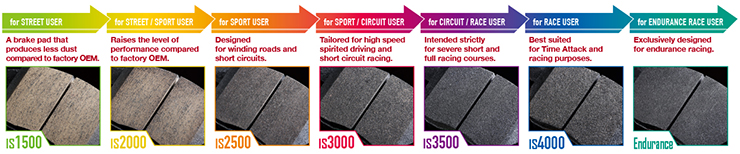

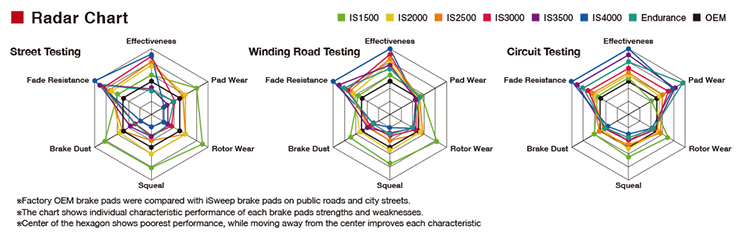

The essential part of brake pad development is choosing the right frictional material in order to exhibit the ideal brake characteristics to suit its targeted usage. Usually the formula requires a compromise; for example, a quiet and noise-free pad cannot be guaranteed against brake fade characteristics, at times increasingly more worse than factory brake pads. A balance of braking properties are very important as well, such as if the effectiveness of the pad compound is increased, so must the initial braking characteristic for which both are correlated with the pedal control factor. Typically, the more experienced the driver, the more they will request for a pad with increased linear braking characteristic with high fade resistance. Seven varying frictional levels and characteristics have been developed to suit a wide array of user needs. These brake pads have undergone rigorous testing such as long-term street testing and countless data logging from circuit use to bring to you the most ideal iSWEEP brake pad.

- Users who are unsatisfied with OEM brake dust.

- Far less brake dust compared to stock factory OEM brake pads.

- Far less brake squeal compared to stock factory pads.

- Roughly 10-20% more effective under normal city driving conditions.

- Improved initial bite and braking control compared to factory OEM pads.

- Tested in extreme winter conditions with effective stable results.

| USE | High Performance Street |

|---|---|

| Material | Non-Steel |

| Temperature Range | Ambient~842℉(450℃) |

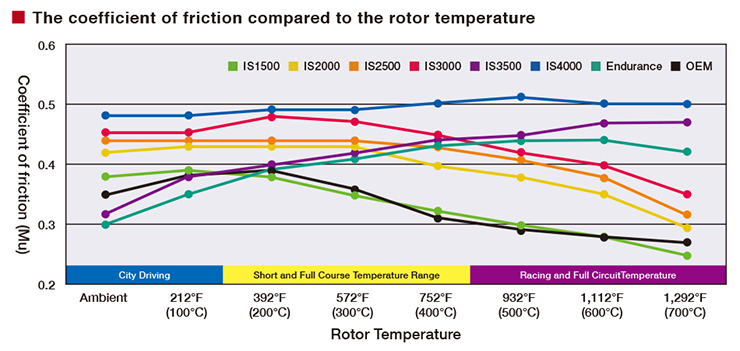

| Coefficient of Friction Ambient~752℉(400℃) |

0.35~0.38 |

| Coefficient 752~1,292℉(400~700℃) |

0.28~0.30 |

- Far more effective performance compared to stock OEM brake pads.

- Versatile brake pad for aggressive street and winding roads.

- Quick reaction to brake pedal input and excellent control of applied force.

- Controlled linear characteristics and stable operation with no sudden or abrupt bite.

| USE | High Performance Street Winding Roads |

|---|---|

| Material | Non-Steel |

| Temperature Range | Ambient~1,022℉(550℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.40~0.42 |

| Coefficient 752~1,292℉(400~700℃) |

0.35~0.38 |

- Designed for users needing superior braking control on the short circuit.

- Specifically chosen pad material for ease of use on the winding roads.

- Control oriented linear characteristics with minimal initial bite.

- Braking performance is not compromised while controlling vibration and squeal.

- Ideal for sports driving for XDS equipped vehicles ※VAG Only

| USE | Winding Roads Mini-Circuit |

|---|---|

| Material | Low-Steel |

| Temperature Range | Ambient~1,112℉(600℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.42~0.45 |

| Coefficient 752~1,292℉(400~700℃) |

0.37~0.40 |

- Users committed to high performance driving and short course racing.

- Excellent high temp response, emphasis on high heat range.

- Users using high grip radial tires or “S” tires on the race track.

- Outstanding braking control during high speed spirited driving.

- Ideal for circuit racing for XDS equipped vehicle ※VAG Only

| USE | Winding Roads Mini-Circuit |

|---|---|

| Material | Low-Steel |

| Temperature Range | Ambient~1,202℉(650℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.45~0.48 |

| Coefficient 752~1,292℉(400~700℃) |

0.40~0.42 |

- Short circuit and full circuit use.

- For racing using “S” tires.

- Consistent and stable character during extended racing periods.

- Proven stable performance at extreme high temperatures.

| USE | Mini-Circuit Full-Cicuit |

|---|---|

| Material | High-Steel |

| Temperature Range | 392~1,382℉(200~750℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.33~0.35 |

| Coefficient 752~1,292℉(400~700℃) |

0.45~0.47 |

- Excellent effectiveness for sprint racing.

- For motorsport use only.

- High coefficient of friction throughout it's temperature range respectfully.

| USE | Time Attack Full Race |

|---|---|

| Material | High-Steel |

| Temperature Range | 212~1,562℉(100~850℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.47~0.49 |

| Coefficient 752~1,292℉(400~700℃) |

0.49~0.51 |

- Designed for endurance racing lasting 3〜4 hours.

- Maintain stable braking performance during long hour endurance racing.

- Excellent anti-wear characteristics

| USE | Endurance Racing |

|---|---|

| Material | High-Steel |

| Temperature Range | 572~1,382℉(300~750℃) |

| Coefficient of Friction Ambient~752℉(400℃) |

0.35~0.38 |

| Coefficient 752~1,292℉(400~700℃) |

0.43~0.45 |